1.Horizontal Well:

1.Horizontal Well:

TCPDC’s teams are skillful in well trajectory plan and control and can offer technical services in horizontal well drilling under complex conditions.

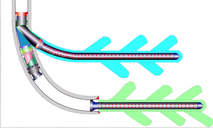

2.Multi-branched Well:

2.Multi-branched Well:

TCPDC made a critical technology breakthrough in the tack jointing at the three phase point of down hole wellbore in multi-branched well drilling. TCPDC’s teams are equipment with 9-5/8” and 7” completion systems for multi-branched well drilling.

3.Underbalanced Well:

3.Underbalanced Well:

TCPDC develops several types of low-density water-based micro foam drilling fluid which can meet the requirements of drilling in different geological formations. TCPDC invented low-density water-based macro foam lost circulation additives and successfully experimented and applied on site. TCPDC developed foam drilling fluid recycling system. In addition, TCPDC has overcome foam fluid stability problem under extremely high temperature and successfully put into practice. TCPDC has formed a complete air drilling system which overcomes the washing and eroding problems of bottom hole assembly in air drilling.

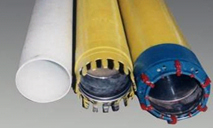

4.Coring

4.Coring

TCPDC’s teams are equipped with 10 series coring equipment which enable them to implement coring operation in ravelly formation, gravel formation, mid-hard formation, hard formation and coal bed. Technologies of long tube coring, coring in horizontal well and ravelly formation are in the leading level in domestic

5.High H2S Well

5.High H2S Well

Test On the basis of risk assessment, through selecting high qualified testing hoses and optimizing the design and joint of hammer union on pipelines, TCPDC’s teams are able to test high H2S wells by hole sealing technology and remote monitoring and control.